How ERVs Work: The Science Behind Fresh Air Systems and Energy Recovery

What Are Energy Recovery Ventilators (ERVs)?

Energy Recovery Ventilators, or ERVs for short, work as part of HVAC systems to swap out old indoor air for fresh stuff from outside while grabbing back around 80% of the energy normally lost during this process. Inside these units sits what we call a heat exchanger, basically a component that moves both warmth (what engineers call sensible heat) and moisture content (latent heat) between the air going out and coming in. What makes ERVs special is this double action approach that cuts down on wasted energy but still keeps the indoor climate comfortable throughout the year. The system has two distinct channels running parallel inside it one pathway pushes out the conditioned air from our homes while another pulls in fresh outdoor air, all without letting them actually touch each other. Studies conducted by folks at the National Institute of Building Sciences point to just how important these devices have become for proper ventilation in today's tightly sealed buildings where traditional windows simply aren't enough to maintain good air quality anymore.

The Role of ERVs in Controlled Ventilation and Fresh Air System Efficiency

Energy recovery ventilators (ERVs) boost how well fresh air systems work by finding a balance between exchanging air and saving energy. Regular exhaust fans just let all that nice conditioned air escape, but ERVs actually take energy from what's being exhausted to prepare the new air coming in. During colder months, these systems grab heat and moisture from the warm indoor air and use it to warm up the cold, dry stuff coming from outside before it gets inside the building. According to those 2023 ASHRAE guidelines on ventilation, this can cut down heating costs by around 30% in homes. The smart controls automatically tweak airflow depending on what the temperature and humidity sensors detect at any given moment, so the system performs well whether it's freezing or sweltering outside.

Energy Transfer Basics: Sensible and Latent Heat Recovery in HVAC Systems

ERVs perform two key types of energy recovery:

- Sensible heat transfer: Moves thermal energy (temperature) between air streams.

- Latent heat transfer: Transfers moisture (humidity) via vapor exchange.

When dealing with humid environments, latent recovery works wonders for managing indoor moisture levels by basically moving extra humidity from fresh air into the exhaust air stream. For those living in drier regions, the same technology actually helps keep indoor spaces from getting too parched when bringing in outside air. Most of these systems rely on either plate or rotary heat exchangers to make this happen. The rotary versions tend to perform better overall, hitting around 70 to 85 percent efficiency for both heat and moisture transfer based on what most HVAC professionals report. What makes energy recovery ventilators so valuable is their ability to keep rooms comfortable while maintaining good air quality, all without putting unnecessary strain on heating and cooling equipment throughout the building.

Key Energy Recovery Mechanisms: Plate vs. Rotary Heat Exchangers

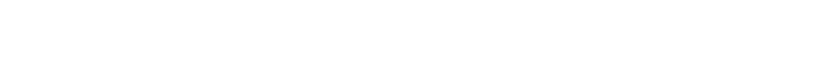

Plate Heat Exchangers: Static Energy Transfer for Stable Efficiency

Plate heat exchangers work by stacking metal plates to move heat from one air stream to another without letting them mix. The system typically grabs back around 80 to 90 percent of wasted heat while keeping performance steady, which is why many homeowners choose these for fresh air systems when they want something simple that doesn't need constant attention. According to recent market data, about 40% of all ERVs installed today are plate type units because they just plain work well over time and don't break the bank too much, especially in regions with milder weather conditions where extreme temperature swings aren't so common.

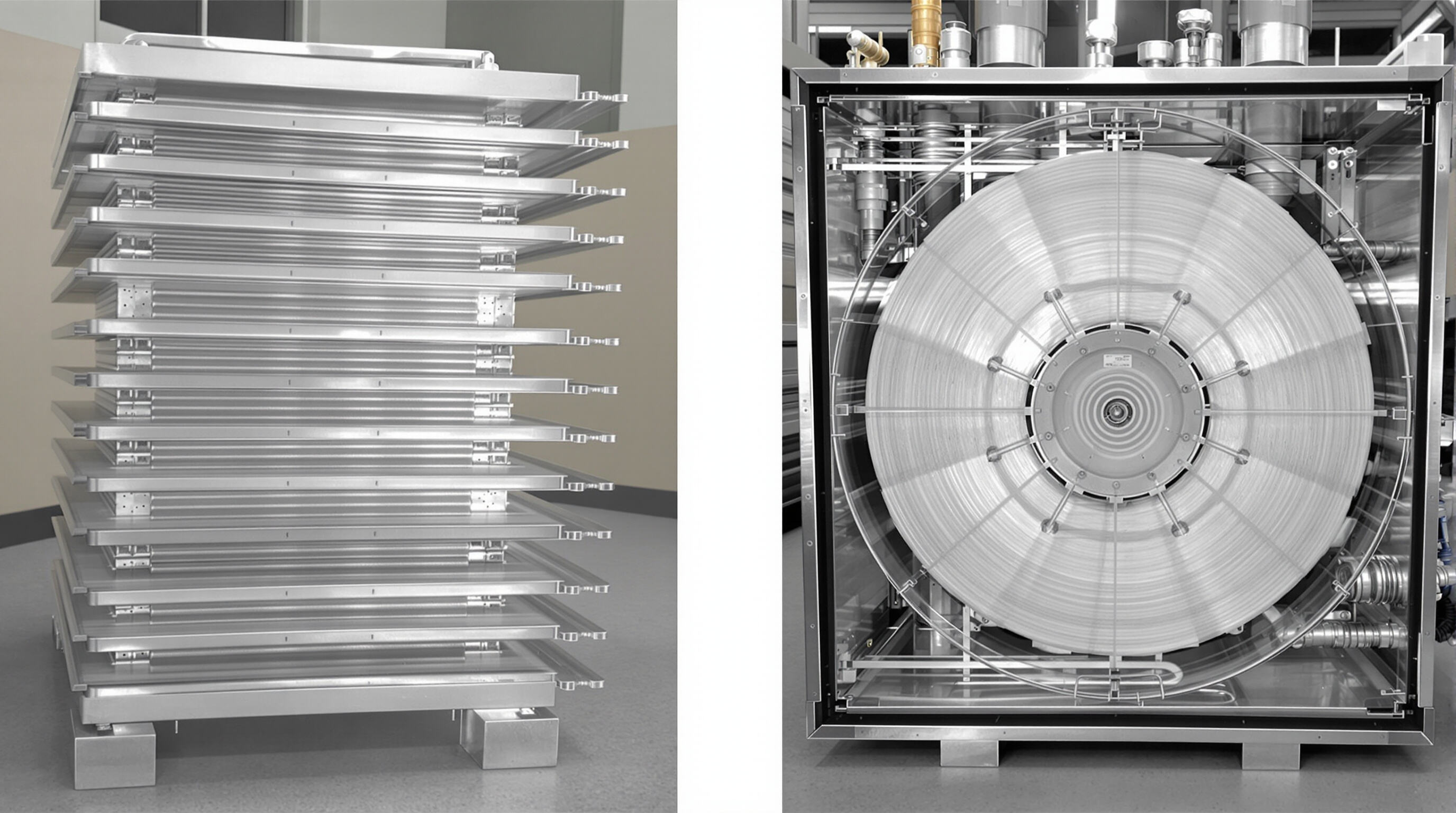

Rotary Heat Exchangers: Dynamic Recovery in High-Performance ERVs

Rotary heat exchangers work by spinning a wheel covered in special moisture absorbing stuff that moves both heat and humidity between different air streams at the same time. What makes these devices stand out is their ability to recover about 20 to 30 percent more latent heat compared to traditional plate systems. That extra efficiency matters a lot for big commercial spaces where ventilation needs run constant and high. Looking ahead, market analysts expect this sector to expand quite nicely, growing around 8.7% year over year until 2033. Why? Because manufacturers keep finding better materials for those spinning rotors, which means they last longer even when exposed to really harsh environments.

Comparative Analysis: Efficiency, Maintenance, and Application Fit

| Factor | Plate Exchangers | Rotary Exchangers |

|---|---|---|

| Heat Recovery Efficiency | 70-85% sensible only | 75-90% sensible + latent |

| Maintenance Frequency | Annual inspection | Quarterly cleaning |

| Ideal Climate | Dry to moderate humidity | High humidity or variable climates |

| Typical Payback Period | 3-5 years | 4-7 years |

Performance Challenges: ERVs in Humid Climates and Moisture Management

Rotary systems definitely have better humidity control capabilities compared to other options, though if installed incorrectly they can actually become breeding grounds for mold right inside the core component. This problem tends to get worse in places with high humidity levels like tropical regions where moisture is constantly present. Plate type designs solve the cross contamination issue entirely, but aren't nearly as good at removing moisture from the air. Many facilities end up needing additional dehumidifiers when operating in really damp conditions. When dealing with harsh weather situations, most experienced HVAC professionals will suggest installing bypass dampers along with proper frost protection mechanisms. These additions help keep the system running smoothly even when temperatures drop below freezing point or swing wildly between extremes.

Improving Indoor Air Quality Without Compromising Energy Savings

Balancing Fresh Air Intake with Thermal Energy Conservation

Modern Energy Recovery Ventilators (ERVs) strike a critical balance: exchanging 70—90% of stale indoor air with filtered outdoor air while retaining 60—80% of heating and cooling energy, according to ASHRAE 2023 guidelines. This process prevents HVAC systems from overworking, maintaining stable humidity levels (±3% variation) even under extreme outdoor conditions.

Reducing Indoor Pollutants, Allergens, and Excess Moisture with ERVs

ERVs filter 95% of PM2.5 particles and reduce volatile organic compounds (VOCs) by 60% through dual-stage filtration. In humid climates, enthalpy wheels actively manage moisture transfer, helping maintain indoor relative humidity between 45—55%—a range recognized by the EPA as optimal for health and building integrity, and effective in suppressing mold growth.

Case Study: IAQ Enhancement in a Sealed Urban Residential Building

A 12-month monitoring project in a LEED-certified high-rise found that ERVs maintained CO₂ levels below 800 ppm (compared to over 1,200 ppm in non-ERV units) while reducing ventilation-related energy costs by 45%. Particulate matter concentrations dropped to 5 µg/m³, meeting and exceeding WHO air quality standards without increasing HVAC runtime.

Quantifying Energy and Cost Savings in Residential Applications

ERV Integration in Residential HVAC: Design, Sizing, and Placement Strategies

Getting ERV systems properly integrated starts with understanding local climate conditions first. For areas with average weather patterns, units ranging from around 30 to 70 CFM generally work well enough. But when dealing with places where humidity stays consistently high throughout the year, going for models that handle moisture better becomes essential. Positioning these units close to where the main HVAC equipment sits helps cut down on energy waste through ductwork. Many contractors actually favor those small rotary core designs during retrofit projects since they take up less room in tight spaces. According to data compiled in last year's Footwear Materials Report, roughly one third of all problems encountered after installing new ventilation systems can be traced back to improper sizing decisions made during installation.

Measuring Energy Reduction: Insights from DOE and ASHRAE Research

Department of Energy (DOE) field studies show ERVs reduce heating and cooling loads by 18—27% in mixed climates. ASHRAE Standard 62.2-compliant systems demonstrate 42% better thermal retention than basic fresh air systems. In cold climates (below 40°F), frost-protection features maintain 81% heat recovery efficiency, compared to 54% in non-optimized units.

Financial Payback: Upfront Costs vs. Long-Term Energy Bill Savings

| Factor | Average Cost Impact |

|---|---|

| ERV Unit | $1,200—$2,500 |

| Installation | $800—$1,600 |

| Annual Energy Savings | $220—$380 (DOE 2023) |

Most households achieve payback within 4—7 years, with ducted systems offering a 23% faster return on investment than ductless configurations.

Case Data: ROI from Zhejiang Embang Environmental Equipment Co., Ltd.

A manufacturer-led study of 62 single-family retrofits in humid subtropical zones revealed:

- 19% reduction in summer peak cooling demand

- 31% lower annual dehumidification costs

- 8.2-year median payback period

Units equipped with humidity-sensing controls delivered 14% higher energy savings than fixed-speed models.

Available Incentives and Rebates for ERV Installation in Green Buildings

Twenty-nine U.S. states offer tax credits covering 15—30% of ERV costs for ENERGY STAR-certified installations. According to the 2023 Multi-Family Energy Report, combining federal tax credits (26 USC § 25C) with utility rebates can shorten payback periods to as little as 3.5 years in energy-efficient home upgrades.

FAQs

What is the primary function of Energy Recovery Ventilators (ERVs)?

ERVs are designed to swap out stale indoor air with fresh outdoor air while recovering a significant portion of the energy typically lost in the process, maintaining indoor comfort efficiently.

How do ERVs contribute to energy savings in HVAC systems?

ERVs save energy by transferring heat and moisture from outgoing air to incoming fresh air, reducing the load on heating and cooling systems and cutting down on energy use.

What are the differences between plate and rotary heat exchangers in ERVs?

Plate heat exchangers transfer heat between air streams without mixing them, are low-maintenance, and suitable for milder climates. Rotary exchangers also manage humidity effectively, are better for high humidity climates, and require more frequent maintenance but offer higher efficiency.

How can ERVs improve indoor air quality?

ERVs filter pollutants, reduce allergens, and manage moisture levels, thereby maintaining optimal indoor air quality by recirculating clean, fresh air indoors.

What are the cost implications and payback periods for installing ERVs?

The initial cost of ERVs ranges between $1,200 to $2,500, with installation costs of $800 to $1,600. Most homeowners can expect to recoup these costs within 4 to 7 years through energy savings.

Table of Contents

- How ERVs Work: The Science Behind Fresh Air Systems and Energy Recovery

- Key Energy Recovery Mechanisms: Plate vs. Rotary Heat Exchangers

- Improving Indoor Air Quality Without Compromising Energy Savings

-

Quantifying Energy and Cost Savings in Residential Applications

- ERV Integration in Residential HVAC: Design, Sizing, and Placement Strategies

- Measuring Energy Reduction: Insights from DOE and ASHRAE Research

- Financial Payback: Upfront Costs vs. Long-Term Energy Bill Savings

- Case Data: ROI from Zhejiang Embang Environmental Equipment Co., Ltd.

- Available Incentives and Rebates for ERV Installation in Green Buildings

-

FAQs

- What is the primary function of Energy Recovery Ventilators (ERVs)?

- How do ERVs contribute to energy savings in HVAC systems?

- What are the differences between plate and rotary heat exchangers in ERVs?

- How can ERVs improve indoor air quality?

- What are the cost implications and payback periods for installing ERVs?

EN

EN