Fundamentals of EPP Energy Recovery Ventilation Systems

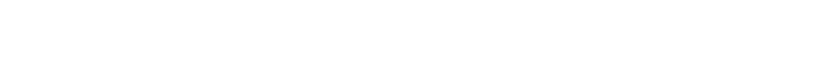

Energy Recovery Ventilation (ERV) systems optimize indoor air quality while conserving energy through sophisticated air exchange technology. These systems continuously replace stale indoor air with fresh outdoor air while retaining up to 90% of thermal energy from exhausted air through specialized heat exchange cores.

By preconditioning incoming air, ERVs maintain consistent indoor comfort levels year-round while cutting heating/cooling costs by 20-50% (ASHRAE 2023). This approach combats "sick building syndrome" by diluting indoor pollutants like VOCs and CO2 without compromising temperature stability—a key advantage in sustainable building design.

EPP Energy Recovery Ventilator: Material Advantages

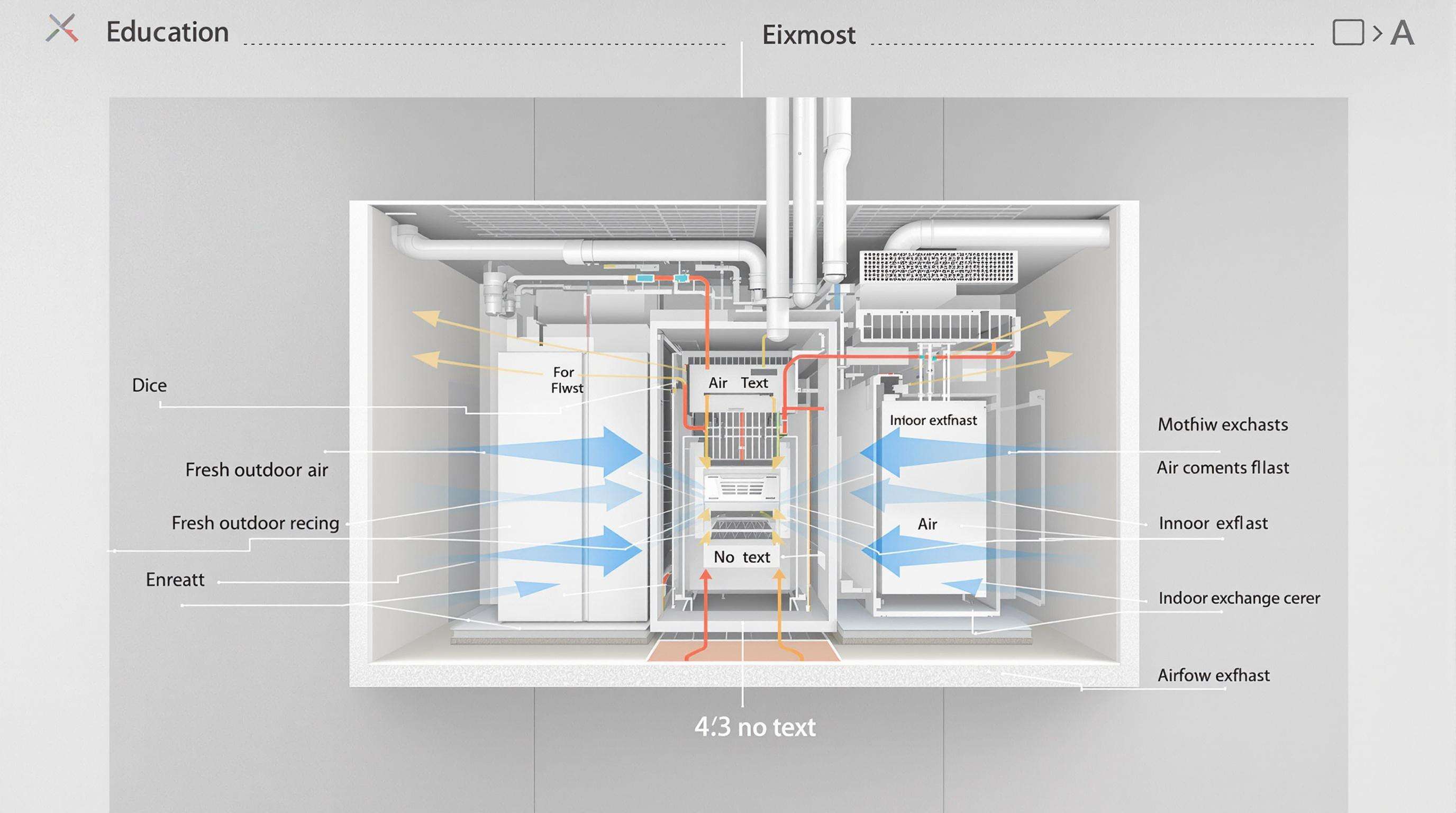

EPP (Expanded Polypropylene) core ventilators offer unique performance benefits. The material's honeycomb structure enables low airflow resistance, reducing fan energy consumption by up to 25% versus traditional substrates. Its thermoplastic composition ensures stability across extreme temperatures (-20°C to 80°C).

Moisture Recovery Efficiency in Humid Climates

In high humidity regions (≥60% RH), EPP cores achieve 85% latent efficiency—outperforming metal counterparts by 18%. This prevents condensation buildup while maintaining balanced indoor humidity, particularly critical for tropical healthcare facilities with strict IAQ standards.

Corrosion Resistance and Longevity

EPP maintains <2% thermal conductivity loss after 15,000 operational hours (ASTM B117 certified), versus aluminum's 9-15% decline. The non-porous polymer resists salt and chemical exposure, eliminating frequent replacement cycles and yielding 60% lifetime savings in industrial settings.

Metal ERV Core Technologies Explained

Metal core ventilators leverage aluminum alloys for rapid thermal transfer between air streams. Their structural strength ensures stability across thermal cycling and airflow pressure fluctuations common in commercial HVAC systems.

Thermal Conductivity Performance Metrics

Aluminum cores achieve thermal conductivity ratings of 120-240 W/mK, enabling heat transfer efficiencies exceeding 90%. Performance remains consistent across temperature differentials (-20°C to 50°C) while maintaining pressure differentials below 100 Pascals—critical for variable-speed systems.

Fire Safety Compliance Standards

Metal cores meet UL 1995 and NFPA 90A certifications without performance-degrading retardants. With melting points exceeding 660°C, they prevent structural collapse during fires while eliminating toxic fume risks associated with synthetic materials.

Energy Efficiency Comparison: EPP vs Aluminum Cores

Sensible Heat Recovery Ratios

Aluminum cores achieve 72-85% sensible heat recovery (ASHRAE 2023), outperforming EPP's 60-75% range, particularly in extreme cold. However, EPP gains ground with surface treatments that enhance convective heat transfer.

Latent Energy Transfer Case Studies

EPP excels in moisture exchange, maintaining 78% latent recovery versus aluminum's 52% in humid conditions. In arctic environments, EPP shows 20% better humidity recovery while avoiding frost risks inherent to metal cores.

Installation and Maintenance Considerations

Proper ERV installation requires precise airflow calibration and professional commissioning. Research shows misconfigured systems waste 15-30% of potential energy savings.

Ductwork Compatibility Challenges

Retrofits often face airflow restrictions from duct diameter mismatches or material incompatibilities. Sealing legacy duct joints is essential to prevent efficiency losses, warranting architectural consultations before installation.

Industry Paradox: Sustainability vs Performance

Material choices present trade-offs between environmental impact and operational efficiency—polymers reduce energy use while metals offer extreme-condition reliability.

Recyclability of Components

Aluminum cores achieve 90% recyclability without quality loss, whereas EPP recycling faces infrastructure limitations, often ending in landfill despite lower production emissions.

Lifecycle Carbon Footprint Analysis

While aluminum production carries high initial CO2 emissions (8-10 tons per ton produced), its longevity offsets impact in some climates. EPP has lower manufacturing emissions but may require more frequent replacement.

Carbon Impact Comparison (Typical 10-Year Period)

| Impact Phase | Aluminum Core | Polymer Core |

|---|---|---|

| Initial Production | ~85 kg CO2e | ~35 kg CO2e |

| Operational Energy | ~220 kg CO2e | ~180 kg CO2e |

| End-of-Life | -5 kg CO2e* | +8 kg CO2e** |

*Negative value indicates emissions avoided through recycling

**Positive value assumes landfill decomposition

FAQ Section

What is an Energy Recovery Ventilation (ERV) system?

An Energy Recovery Ventilation system is a technology that optimizes indoor air quality and conserves energy by exchanging stale indoor air with fresh outdoor air while retaining significant thermal energy through a heat exchange process.

How do EPP cores differ from metal cores in ERV systems?

EPP cores use a honeycomb structure material that reduces airflow resistance and enhances moisture recovery efficiency, especially in humid climates. Metal cores, particularly aluminum, excel in rapid thermal conductivity and fire safety compliance.

What are the environmental considerations of using aluminum vs EPP cores?

Aluminum cores have higher recyclability and a longer lifespan, although initial production is CO2 intensive. EPP has lower emissions during production but faces recycling challenges, often ending up in landfills.

EN

EN