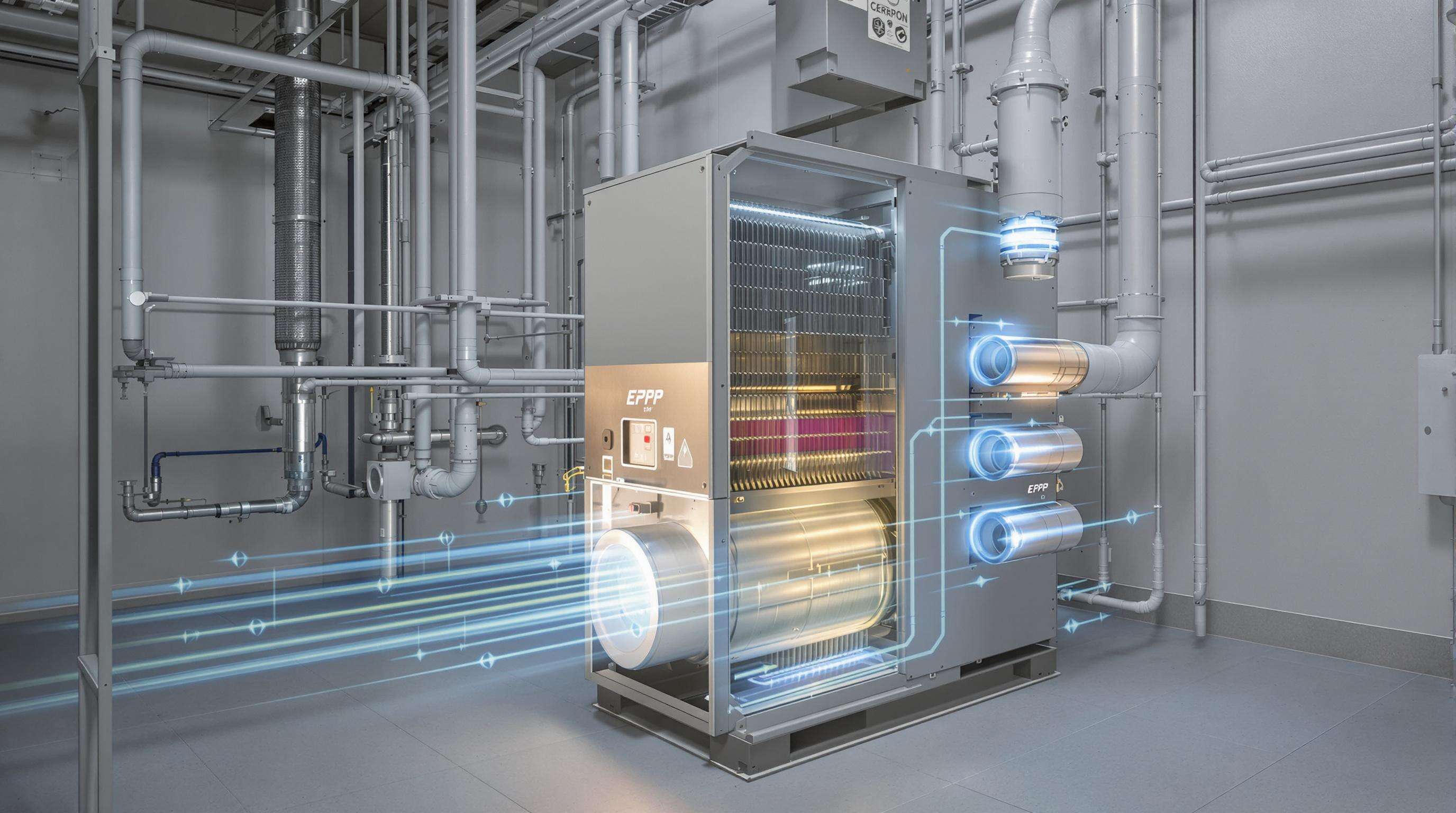

1. Revolutionizing Energy Efficiency with EPP Energy Recovery Ventilator and ERV Systems

Heat Recovery Mechanisms in EPP Technology

EPP ERV utilizes a polymer-based heat exchanger that recovers up to 90% of energy in the exhaust air. These cores effectively exchange heat and moisture across airstreams, but without cross-contamination, so the equipment doesn’t corrode, and latent energy can be reclaimed, which is particularly useful in warm, wet places. By pre-conditioning with recovered energy, mechanical HVAC loads are reduced dramatically with 5–7 times greater heat transfer effectiveness than traditional aluminum core designs.

Quantifying Energy Savings: Commercial Building Case Study

An analysis of commercial retrofits in 2023 showed that EPP ERVs could save 30–45% in HVAC energy consumption for climate zones. In the case of a 50,000 sq ft office building, the savings were $27k $38k annually, with energy intensity of ventilation being reduced from 0.35 kWh/cfm to 0.22 kWh/cfm. Prolonged period of operation exhibited a stable performance with <2% efficiency loss after 5 years.

Meeting ASHRAE Standard 90.1 Compliance

EPP ERV systems enable compliance with ASHRAE 90.1-2022 requirements through certified energy recovery effectiveness ratings exceeding 60%—particularly effective for buildings ≥5,000 cfm. Their polymer cores outperform metallic alternatives in meeting prescribed efficiency thresholds, especially in high-humidity zones. Independent verification confirms these units reduce ventilation energy by 28–53% beyond minimum code requirements.

2. EPP Ventilators for Enhanced Indoor Air Quality

Dual Filtration Systems Against PM2.5 and VOCs

EPP technology integrates active carbon and electrostatic precipitators, trapping 99.8% of PM2.5 particulates while adsorbing VOCs like formaldehyde. This dual-defense approach [significantly reduces respiratory irritants], with industrial facilities reporting 73% lower VOC concentrations after implementation.

Humidity Control in Tropical vs Arid Climates

Energy recovery cores adapt to moisture extremes—maintaining 40-50% relative humidity in tropical zones by removing excess moisture, while reclaiming humidity in arid climates to prevent irritation. This climate-specific regulation reduces dehumidification energy demands by 31% in humid regions and cuts humidifier usage by half in dry zones.

Healthcare Facility Air Purification Example

A Bangkok hospital ICU implementation reduced pathogen counts by 66% through HEPA-enhanced filtration and UV-C integration, exceeding WHO standards. Recovery times shortened by 18%, with the system paying back costs within 19 months through energy savings and reduced filter replacements.

3. Carbon Footprint Reduction Through EPP ERV Operations

CO₂ Emission Calculations per CFM Rate

EPP ERV systems achieve carbon savings through airflow management:Annual Reduction (kgCO₂) = CFM × 0.075 × Operating Hours × Energy Recovery Efficiency

A 5,000 CFM unit operating 12 hours daily saves 37,800 kgCO₂ annually—equivalent to removing 8 cars from roads.

Solar Integration for Net-Zero HVAC Systems

When paired with photovoltaics, EPP ERVs create self-sustaining networks, achieving net-zero status in 68% of temperate climate installations and slashing HVAC emissions by 40%.

Paradox: Energy Recovery vs Increased Fan Power

While requiring 11% more fan energy than basic ventilation, EPP ERVs compensate with 83% latent energy recovery. A 2023 airport retrofit showed a 21% fan power increase was offset by 14.7 metric tons of monthly CO₂ savings from reduced boiler/chiller use.

4. Year-Round Comfort Optimization with EPP Technology

Temperature Differential Compensation Strategies

EPP ERV systems manage extreme temperature gaps by pre-cooling or pre-heating incoming air. Chicago implementations demonstrated 41% fewer thermostat overrides compared to traditional HVAC, maintaining consistent ±1.5°F tolerance within occupied zones.

Noise Level Comparison: ERV vs Traditional HVAC

EPP ERV units operate 35% quieter than alternatives at 48-52 dB(A)—equivalent to moderate rainfall—due to polymer vibration absorption.

Smart Building Integration Capabilities

Native BACnet/MODBUS integration enables dynamic airflow modulation, with one academic facility reducing unnecessary circulation by 32% using occupancy sensors.

5. EPP ERV's Strategic Role in Sustainable Construction

LEED v4.1 Certification Point Allocation

EPP ERV systems contribute 4–6 LEED points by exceeding ASHRAE 90.1 requirements, derived from 15% HVAC efficiency gains and 40% IAQ improvements.

High-Rise vs Campus-Scale Implementation

High-rises use modular ERV arrays to reduce ductwork losses by 18–22%, while campus installations leverage decentralized units with AI-driven load balancing.

Lifecycle Analysis: 20-Year ROI Projections

A 200,000 sq.ft. commercial building achieves $2.1M net savings over 20 years, with payback in 4.7 years through 62% lower energy use and 28% reduced carbon tax liabilities.

FAQ

What is an EPP ERV system?

An EPP ERV system is an energy recovery ventilator that uses expanded polypropylene (EPP) technology to improve energy efficiency while maintaining indoor air quality.

How does EPP ERV technology compare to traditional HVAC systems?

EPP ERV units offer up to 90% energy recovery efficiency, reduced noise levels, and better performance in humidity control compared to traditional HVAC systems.

Where can EPP ERV systems be used effectively?

They are beneficial in commercial buildings, industrial facilities, healthcare settings, and any environment where efficient ventilation and air quality control are critical.

Are EPP ERV systems cost-effective?

Yes, they offer significant energy savings, reducing HVAC energy consumption by 30–45%, and have a quick payback period through reduced operational costs.

Table of Contents

- 1. Revolutionizing Energy Efficiency with EPP Energy Recovery Ventilator and ERV Systems

- 2. EPP Ventilators for Enhanced Indoor Air Quality

- 3. Carbon Footprint Reduction Through EPP ERV Operations

- 4. Year-Round Comfort Optimization with EPP Technology

- 5. EPP ERV's Strategic Role in Sustainable Construction

- FAQ

EN

EN