What is an EPP Energy Recovery Ventilation (ERV) System?

ERV systems, short for Energy Recovery Ventilation systems, are sophisticated HVAC devices that exhaust stale indoor air as they bring in outdoor air, all the while exchanging heat and moisture between the two airstreams. Comparing to traditional airflow methods, which simply extract outgoing air and replace it with incoming air, ERVs precondition incoming air with energy from outgoing air, resulting in 30–50% less energy usage. This is the technology that insures a constant supply of fresh air without sacrificing thermal efficiency – vital for today’s well-sealed new homes, where natural air leakage is not enough to provide optimal indoor air quality.

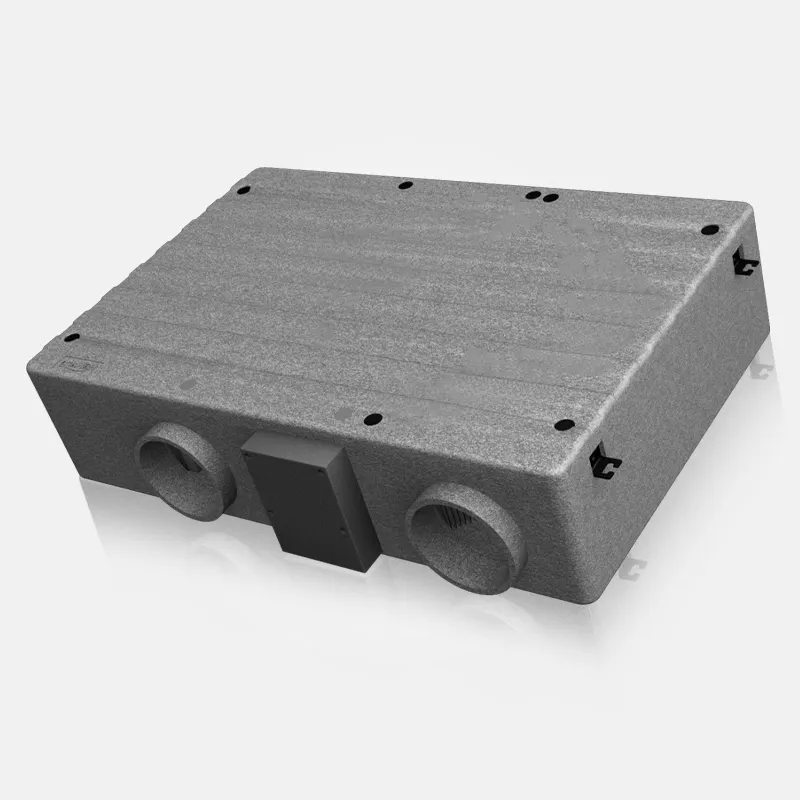

Core Components of EPP ERV Units

Modern ERVs rely on two key components for energy recovery: polymer-plate heat exchangers with moisture-permeable membranes that transfer heat and humidity without air mixing, and dual ECM blowers that maintain balanced airflow—preventing pressure imbalances. These parts operate within an insulated cabinet to minimize condensation and thermal bridging.

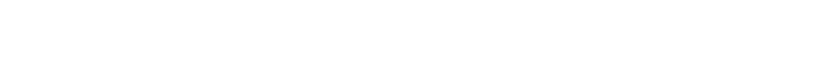

The Thermodynamics Behind Energy Recovery

ERVs utilize enthalpy transfer principles, where heat and moisture naturally move from high-concentration zones to lower ones. In summer, warm, humid exhaust air pre-cools and dehumidifies incoming air; in winter, the process reverses. Heat exchangers recover 60–80% of would-be-lost energy, as documented by ASHRAE performance data.

How EPP ERVs Reduce HVAC Energy Consumption

Heat Exchange Efficiency Metrics (Sensible vs Latent)

EPP ERVs save energy through dual recovery mechanisms: sensible heat exchange (temperature transfer) and latent recovery (moisture transfer). Premium units achieve 70-90% effectiveness, reducing HVAC loads by 35-45% compared to traditional ventilation.

Case Study: 32% Load Reduction in Commercial Buildings

A 2023 study of six Midwestern office buildings (15-25k sq ft each) showed an average 32% annual HVAC energy reduction after ERV installation, with savings of 28,000 kWh electricity and 4,200 therms of gas per building. Payback periods averaged 2.8 years through lower utility and maintenance costs.

ASHRAE Standards for Ventilation Optimization

ASHRAE Standard 62.1 mandates outdoor air requirements that can increase HVAC loads by 25-40%. ERVs meeting ASHRAE 90.1-2022 requirements offset 60-80% of this energy penalty, making them essential for retrofit projects.

Cost-Benefit Analysis of EPP Energy Recovery Ventilators

Upfront Costs vs 5-Year Operational Savings

While ERV systems cost 20-40% more upfront than basic units, their lightweight polypropylene construction reduces material costs by 15-25% compared to metal alternatives. Over five years, average savings of $0.30 per sq ft annually typically offset 110-130% of the initial premium, with most projects achieving payback within 3.8 years.

HVAC Equipment Downsizing Opportunities

ERVs precondition supply air, reducing heating/cooling needs by 25-40% per 10,000 CFM. This allows:

- Smaller boilers/chillers

- Up to 30% ductwork reduction

- Lower-capacity air handlers

New constructions save $0.80-$1.20 per sq ft on equipment costs, with 12-18% lower maintenance fees from reduced runtime strain.

Utility Rebate Programs for ERV Installations

Many utilities offer 10-25% rebates for ENERGY STAR®-certified ERVs, which often qualify due to 70% recovery efficiency. Federal tax deductions of up to $1.80 per sq ft are available in climate zones 4-7, shortening payback periods by 14-18 months.

EPP ERVs vs Traditional Ventilation Systems

Energy Waste in Constant Air Volume Systems

Constant Air Volume (CAV) systems waste energy by continuously reheating/cooling unconditioned air, consuming 30-40% more energy during peak seasons. Studies show CAV systems use 50% more energy than demand-controlled alternatives in mixed-use buildings.

Infiltration Loss Prevention Mechanisms

ERVs maintain neutral pressure, preventing 15-25% of HVAC loads caused by air leakage. With 70% sensible energy recovery, they cut total heat loss by up to 60% versus traditional systems.

Optimizing EPP ERV Performance in Different Climates

Frost Control Strategies for Northern Regions

Sub-zero temperatures risk frost buildup, reducing efficiency by 40%. Modern ERVs counter this with:

- Pre-heating intake air above dew point

-

Automated defrost cycles during cold snaps

These measures sustain 85% thermal recovery even at -20°C.

Humidity Management in Tropical Zones

In humid climates, EPP ERVs prioritize moisture transfer, reducing dehumidification loads by 15-30%. Adjustable dampers and variable-speed controls adapt to real-time conditions, maintaining 45-55% indoor humidity—critical for mold prevention.

FAQ

What is the primary function of an Energy Recovery Ventilation (ERV) system?

The primary function of an ERV system is to exchange heat and moisture between incoming and outgoing airflows, providing fresh air while maintaining energy efficiency in HVAC systems.

How do ERVs contribute to energy savings?

ERVs contribute to energy savings by preconditioning incoming air using energy from outgoing air, thereby reducing HVAC loads and energy usage by 30-50% compared to traditional methods.

What is the difference between sensible and latent heat exchange?

Sensible heat exchange refers to the transfer of temperature, while latent recovery deals with the transfer of moisture. Both types improve the efficiency of HVAC systems.

Can ERVs be used in different climate zones?

Yes, ERVs are designed to work efficiently in various climatic conditions, with specific features addressing frost control in colder regions and humidity management in tropical climates.

Table of Contents

- What is an EPP Energy Recovery Ventilation (ERV) System?

- Core Components of EPP ERV Units

- The Thermodynamics Behind Energy Recovery

- How EPP ERVs Reduce HVAC Energy Consumption

- Heat Exchange Efficiency Metrics (Sensible vs Latent)

- Case Study: 32% Load Reduction in Commercial Buildings

- ASHRAE Standards for Ventilation Optimization

- Cost-Benefit Analysis of EPP Energy Recovery Ventilators

- Upfront Costs vs 5-Year Operational Savings

- HVAC Equipment Downsizing Opportunities

- Utility Rebate Programs for ERV Installations

- EPP ERVs vs Traditional Ventilation Systems

- Energy Waste in Constant Air Volume Systems

- Infiltration Loss Prevention Mechanisms

- Optimizing EPP ERV Performance in Different Climates

- Frost Control Strategies for Northern Regions

- Humidity Management in Tropical Zones

- FAQ

EN

EN